Supply Chain Disruption: Is Now the Time for Contractors to Warehouse or Carry Inventory?

Vinyl windows used to have a two-week lead time. According to Stan Miller, who runs a commercial supply store in Missouri, supply chain challenges have pushed availability to 12 to 14 weeks. Materials delays and resulting price increases have permeated every part of the construction industry, and they won’t ease any time soon.

Supply chain challenges “will get worse before they get better,” said Tim Uy, an economist at Moody’s Analytics, in a November article. There is a perfect storm at work: A winter wave of COVID-19, power outages and rationing in China, truck driver shortages in the U.S. and abroad, the impact of extreme climate events on commodities, and soaring consumer and energy demand ahead of the holiday season.

Chaos in the supply chain has taken a toll on general contractors particularly. Four out of 5 respondents to FMI’s fourth quarter Construction Industry Round Table (CIRT) survey were seeing delays from supply chain issues, and 1 out of 5 respondents had experienced canceled projects.

According to a September survey by the Associated General Contractors of America (AGC) and Autodesk, 93% of firms were affected by materials price hikes, and nearly 9 out of 10 had experienced project delays. Midyear price relief on components like steel and lumber had reversed late in 2021, when lumber rose 40% from September to October, and the consumer price index hit 6.2%.

Characteristically, construction companies respond nimbly to industry challenges, and this one has been no different. Contractors worked with owners to pull forward critical material purchases, sent project teams to factories to check on material production, doubled down on tracking materials and conducting pull-planning, planned for various budget and schedule contingencies, and, perhaps most notably, increased their willingness to buy and warehouse materials months in advance of when they might be needed on the job site.

Purchasing and holding long-lead inventory of construction materials can provide advantages for certain projects or customers, but also brings with it carrying costs, increased risk and other considerations for your business.

Advantages of Holding Inventory

It has always been true that those contractors who have shorter lead times for critical path materials have a competitive advantage when bidding work. In the current environment of supply chain uncertainty, this competitive advantage is even stronger.

Consider bidding on a hypothetical distribution facility project that you believe will be determined by delivery of the roofing material specified by the customer. Can you leverage your construction knowledge, your shop’s ability to modify or adapt an alternate roofing material, your relationship with roofing material manufacturers, or your ability to buy and hold inventory?

What if you could get a suitable alternate roofing material weeks, if not months, in advance of your competitors? What if you could provide your customer with certainty that it would be on its job site the moment it was needed? This is why firms are holding and warehousing inventory, sometimes even before they’ve won the job.

Holding and warehousing inventory can offer a clear advantage because:

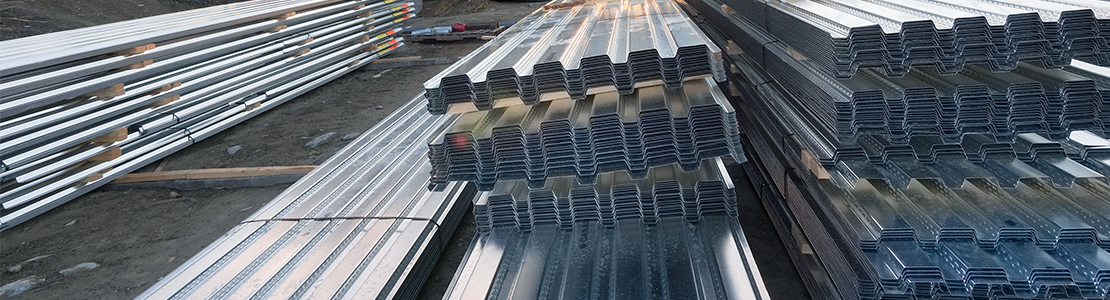

- The items have limited availability and are on the critical path. Items on the critical path present a significant risk to the project schedule if delayed. Examples include roofing systems, insulation, lumber, trusses and other fabricated structural steel, appliances and other durable manufactured goods.

- The items have a long lead time and are capital- intensive to manufacture, but can be customized or modified in your yard, shop or prefabrication department for a specific customer application. In this category are materials and equipment such as electrical switchgear (especially for general commercial or distribution applications), material conveyor sections, motors and pumps, etc.

- Holding a limited “safety stock” of the item can minimize field stockouts or field delays. Safety stock describes excess quantities of an item held in inventory to reduce the risk that it will be out of stock. If these items are not available to your field personnel on a particular day, your teams will not be able to install work as planned. Examples are materials commonly used on multiple project types, such as fasteners, wire and cable, urethane/polyurethane products and other consumables.

Warehousing can provide a buffer against supply chain disruptions and competition for materials, the ability to customize, faster delivery and sometimes even a price advantage. However, without a clear strategy and an understanding of the risks, many companies will find that the potential costs outweigh the benefits.

Costs of Holding Inventory

Many construction firms adapted to a world that rewarded just-in-time deliveries, and warehousing is clearly a right-hand turn from this lean approach. When you buy materials early and store them until needed, you are effectively adding in cost where it had previously been trimmed. You are also increasing the financial risk to your company.

The high cost of warehousing was poignantly captured in the story of the Brooks Brothers retail bankruptcy, which left the owners of a Massachusetts warehouse saddled with the job of trying to liquidate an inventory of mannequins, sewing machines and neon signs. The owners, Chip and Rosanna LaBonte, had to sell their house to fund junk removal.

Unlike Brooks Brothers — or any other retailer, distributor or manufacturer — your company is much less likely to have the organizational skills and competencies related to holding and managing inventory. Because managing inventory is not a core part of your business, it may be more likely that you will overlook inventory risks or undercount carrying costs.

As a rule of thumb for manufacturers and retailers, inventory carrying costs can be as high as 20% of the cost of the materials. This number goes up for unique or big-ticket items like machinery and down for frequently used bulk items. Because the construction materials that you might inventory are typically unique to a project, are big-ticket items and take up considerable storage space, inventory carrying costs may be even higher than 20%.

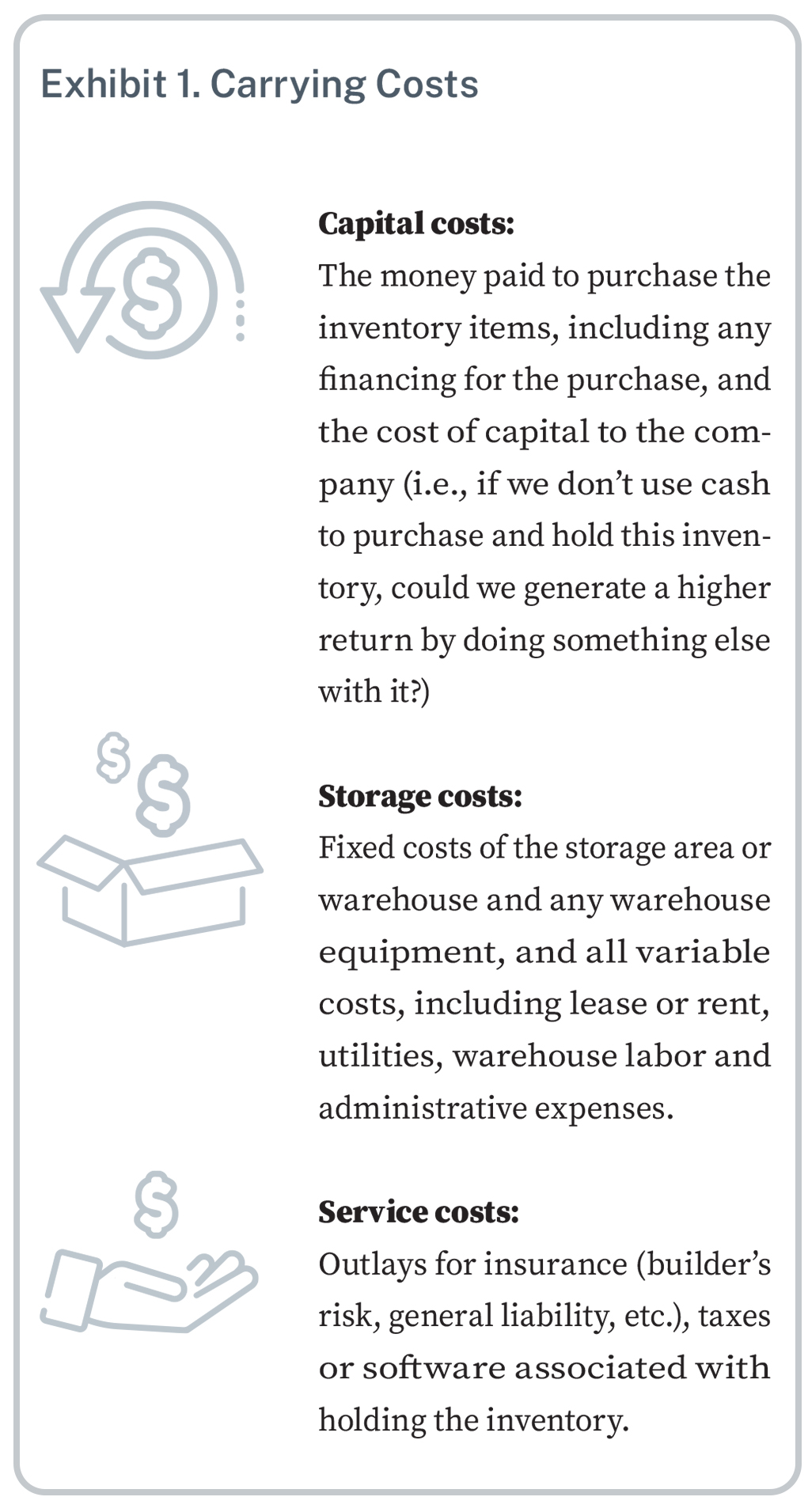

Carrying costs include capital costs (the cost to buy the inventory), storage costs (costs to store and track the inventory) and service costs (insurance, software, taxes associated with the inventory) Exhibit 1. Just like putting together a detailed project budget, it’s important that your organization understands all carrying costs before you decide to buy and hold inventory.

You’ll also need to think through and make allowances for breakage, spoilage, theft or other types of inventory shrinkage. What’s the likelihood that the materials are damaged by water, fire or an errant forklift driver? Who would pay for these costs? Your material likely also has a risk of obsolescence — that the items are never used. The customer may change its mind, the project may face delays or cancellation, or the design may shift, which could leave you having to absorb the sunk costs of inventory you’re holding.

Lastly, if you buy construction materials and warehouse them — and can’t direct-cost them to a project — this inventory will likely be reflected as a long-term asset on your company’s balance sheet. This may not be looked upon favorably by your bonding or surety company or by the owners or investors of your company.

In Summary

Holding and warehousing inventory may be a winning strategy for your firm in the current environment of supply chain disruption and uncertainty. It might help you win more work if your customer places a high value on schedule delivery.

But know that holding and warehousing inventory increases your costs and increases the risk to your firm. These risks are outside of your core business and could be substantial. You should earn a significant premium for providing this benefit to your customers and ensure you are getting paid for the risk you are taking.

Have a full understanding of the carrying costs, the risks and how much you deserve to get paid for those risks before you decide to implement the strategy of buying and warehousing inventory.

Read the first article in this series, Supply Chain Disruptions: What You Need to Know.