Supply Chain Disruptions: What You Need to Know

Global supply chain disruptions have disrupted the engineering and construction industry, with all eyes now watching the horizon. A boom is underway, but firms can’t get enough of the materials they need in hand, nor can they find the staff to build once they do have supplies.

Nine out of 10 firms are currently experiencing project delays, according to a September survey by Autodesk and the Associated General Contractors of America (AGC).1 The main culprits are shortages of materials, delivery delays and longer lead times. Ninety-three percent of firms say that rising materials costs have impacted projects, something they often cannot pass onto customers.

It is a new paradigm for risk, and all eyes are on the supply chain, which is under pressure from end to end:

- Materials shortages: The freeze in Texas in early 2021 shut several petrochemical plants,2 resulting in shortages of plastics and polymers needed as raw materials for a variety of products. Meanwhile, in May lumber prices were up 406% from the previous year, driven by high tariffs on Canadian imports, increased demand amid a housing boom, and issues with transporting materials.3 This has slowed a historic rise in housing starts, which hit a 15-year high in March 2021 at 1.725 million units and fell 7% on a seasonally adjusted rate in July. Copper prices hit a 10-year high this year as well in a frenzy that saw a Tesla plant among the job sites targeted for theft of copper materials. Elsewhere, shipping delays have caused shortages of steel joists, semiconductor chips, insulation, stainless steel and PVC piping.4

- Competition for materials: At the end of 2020, Amazon operated more than 300 million square feet of space in the U.S.,5 an increase from less than 200 million square feet at the end of 2018. It’s hard to conceptualize the scale, but Amazon has added six Disneylands worth of real estate — inclusive of both parks and all hotels — to its distribution network in just two years, as reporter Paris Martineau put it.6 The company also plans to add last-mile distribution centers and begin 14 new renewable energy projects that will make Amazon the largest corporate purchaser of renewable energy in the world.7 The ever-expanding footprint of Amazon properties is putting an incredible strain on the construction materials market, resulting in further price escalation and delays.

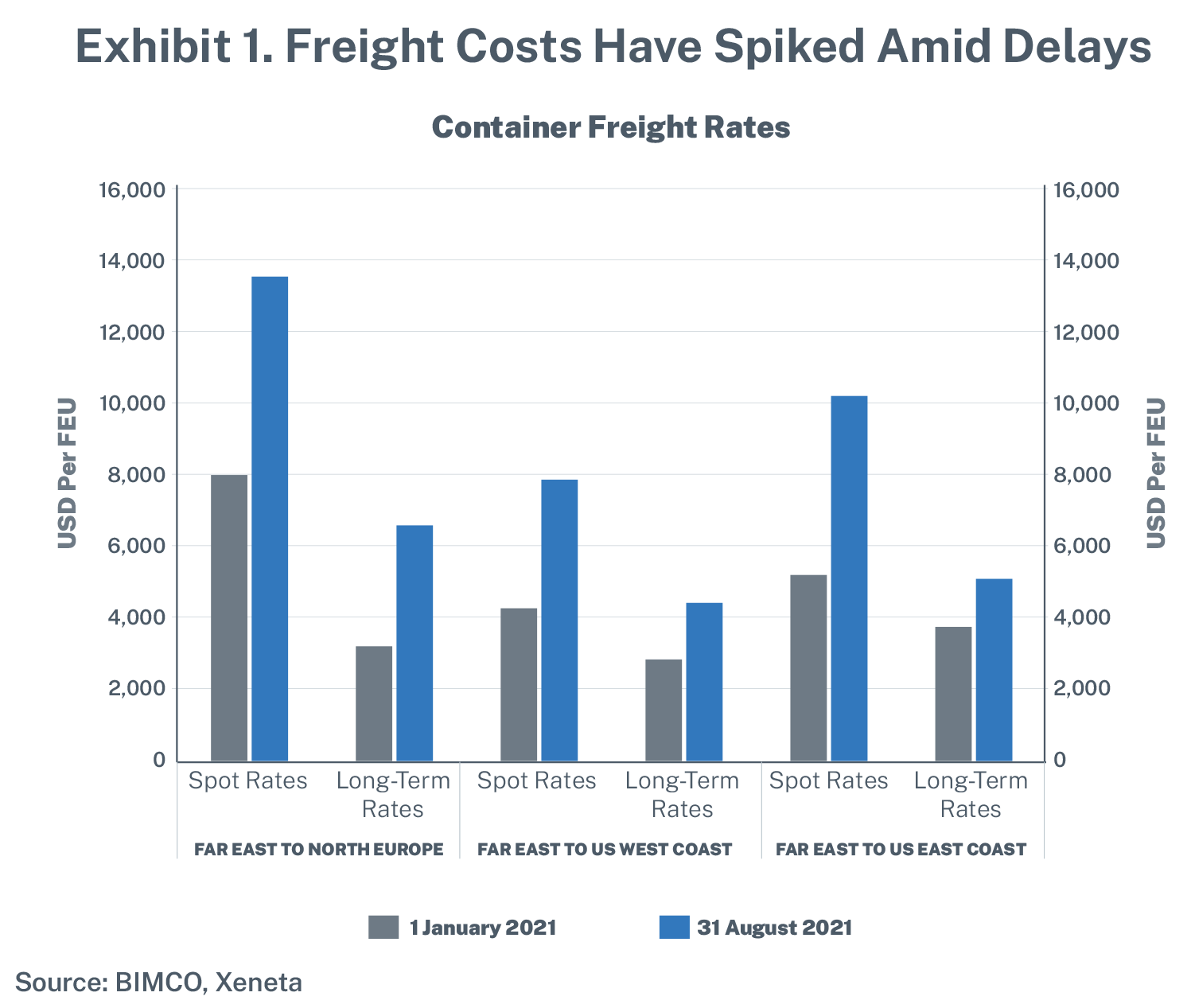

- Transportation delays: Pandemic-related port closures and congestion have caused record delays in international shipping, with 90% of container ships having to wait for a berth and importers facing significant hikes in freighting costs.8 Shipping delays have caused backups in the trucking industry. “Not only are there broader supply-chain issues, like semiconductors, holding tonnage back, but there are also industry specific difficulties, including the driver shortage and lack of equipment,” explained Bob Costello, chief economist at American Trucking Associations.9

Amid supply chain disruption and price spikes, some clients are opting to delay putting work out to bid or starting projects and, in some cases, asking to rebid on work. While risk has grown and is more likely to be shouldered by contractors, there are things you can do, from your initial proposal development through project execution, to respond to the current environment.

During the preproposal phase

The best positioned contractors are viewed as trusted advisors by their customers. The preproposal phase, where you are first beginning to discuss a potential opportunity with a customer, is the time where your industry knowledge can add the most value and help mitigate potential project risks.

Some topics to consider discussing with customers, particularly those who are newer to the industry include:

- Current trends in materials pricing and known potential for delivery disruption.

- Design decisions (e.g., trusses, precast versus cast-in-place, traditional versus metal stud) that may have an impact on the project schedule.

- Your success stories in managing supply chain disruption and pricing escalation.

- How your customer can mitigate cost risks and ensure schedules are met by committing to design decisions as early as possible.

Developing your bid proposal

In an environment where construction material prices and availability may be relatively volatile, winning proposals will clearly set out important design decisions that affect schedules and costs, and your team’s plan to mitigate them.

During the proposal development phase, your team should incorporate the following considerations into your plan:

- Differences in materials pricing or volatility and expected schedule for receiving material after placing an order.

- The benefits of locking in pricing and key design elements via an early letter of intent (LOI) for subcontractors and trade partners to purchase materials. You can incentivize this by putting an expiration on the bid pricing.

- Your plan for holding contingencies at each stage of the build, managing schedule risk, sharing any cost savings, and communicating potential materials delays during the preconstruction and construction phases.

- Your staffing plan for mitigating the risk of supply chain disruption.

- Alternate strategies to minimize materials cost volatility or risk to schedule (e.g., warehousing).

Consider devoting an entire section of your proposal to the ways in which you understand and have a plan to mitigate pricing and schedule risks. This is an opportunity to further position yourself as a trusted advisor and differentiate your company’s proposal from those of your competitors.

Going under contract

After winning the work, make sure your contract addresses the many contingencies of a project and provides clear risk allocation. Contract negotiations are the appropriate time to solidify the process for managing (and getting compensated for)

schedule delays and changes in materials pricing, as well as outlining communication expectations. Do not be afraid to walk away from a project if you will not be compensated fairly for the additional material risk.

Consider negotiating into your contract:

- Appropriate contingency for potential material price escalation either as a separate line item or within your subcontractor line items.

- Payment for any increase in your builder’s risk policy premiums for materials that will be stored to make sure you’re covered in case of theft.

- An addition to the force majeure language to include unusual delay in deliveries or supply chain disruption. This may be a worthwhile way to protect yourself against potential damages even if it means negotiating a small reduction in your fee.

- Clarifying if or how you will be compensated for schedule delays or significant price changes associated with materials.

- Outlining the plan for communicating and resolving issues related to changing material prices or deliveries.

- Expectations for the customer to approve certain shop drawings or submittals, or respond to requests for information within a specified timeframe.

Prejob planning and buyout

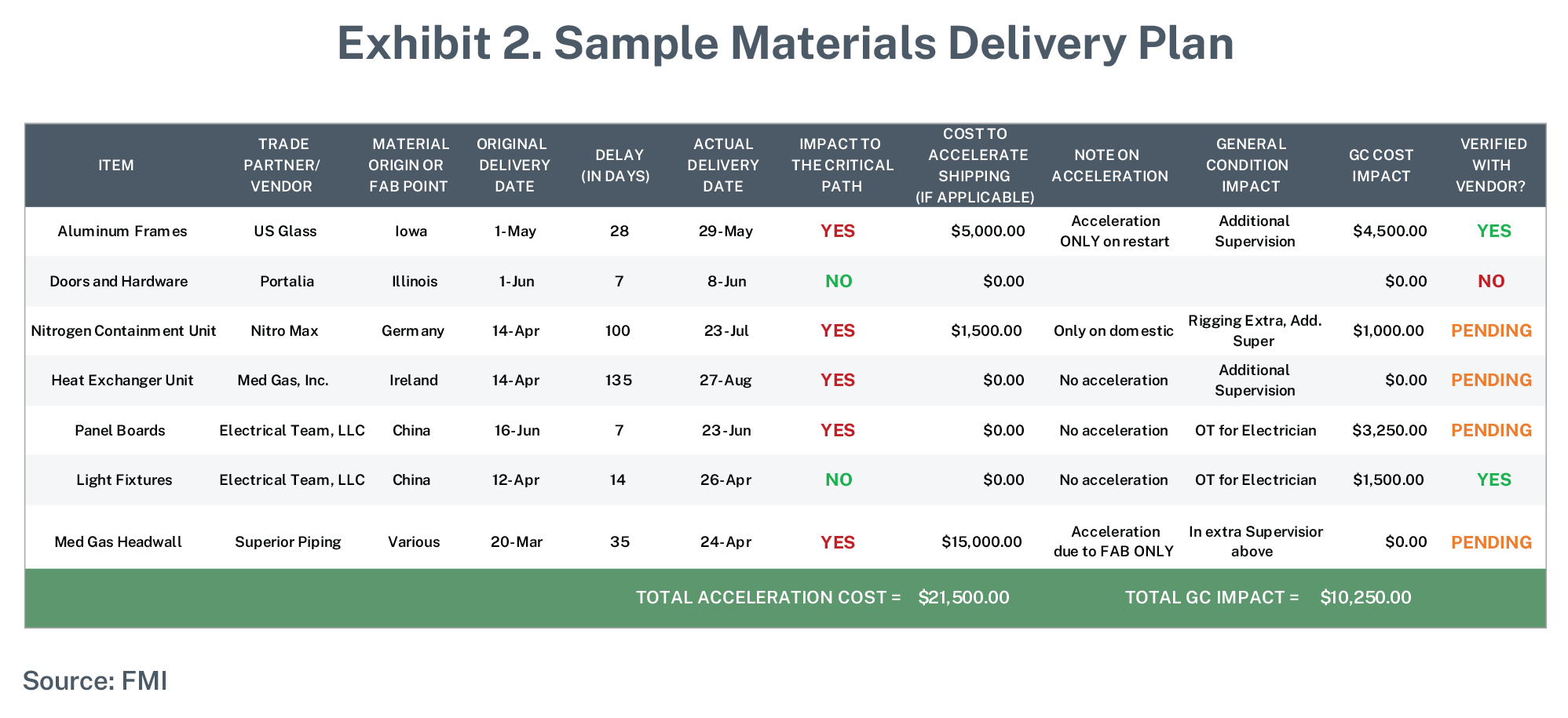

Costs and schedules are honed during prejob planning. Your preexecution plan and critical path method (CPM) schedule should be developed with input from the field and your subcontractors, and should recognize contingencies for alternate vendors and expedited materials.

You should identify:

- Buyout plans for key materials, including dates, fixed prices and storage arrangements.

- Alternate vendors and options for expedited delivery.

- Staffing needed to manage material deliveries, storage and logistics.

- Potential impacts to the schedule and costs of material delivery delays. These should be communicated to the client as well.

Developing a thorough CPM schedule and conducting buyout as early as possible can both reduce your overall risk.

Once construction begins

Detailed planning and early ordering can mitigate inevitable delays, but you should also discuss supply chain issues and materials deliveries at all project team and subcontractor coordination meetings. This is where plans for managing materials deliveries, pricing changes and schedule impacts come into play.

Global disruptions to the supply chain are rare but not unprecedented. It’s appropriate to take on risk as long as it rewards those who can identify, assess and plan for disruptions, while building strong relationships with suppliers and owners. Drafting solid contingencies in the planning stages through project execution can ensure you are being appropriately compensated for the risks you’re taking.

1 “Construction Workforce Shortages Reach Pre-pandemic Levels Even as Coronavirus Continues to Impact Projects & Disrupt Supply Chains.” Associated General Contractors of America. Sept. 2, 2021.

2 Matthews C, et al. “Texas Freeze Triggers Global Plastics Shortage.” Wall Street Journal. Mar. 17, 2021.

3 Moore A. “Ask an Expert: Why Is There a Lumber Shortage?” NC State: College of Natural Sciences. May 19, 2021.

4 Yoders J. “What’s Behind the Materials Price Spikes?” Engineering News-Record. Mar. 24,2021.

5 “Form 10-K.” Amazon.com Inc. Feb. 2021.

6 Martineau P. “Amazon’s Space Race: Delivery Hubs Near Cities, Airports Propel Warehouse Growth.” The Information. Aug. 18, 2021.

7 “Amazon.com Announces Second Quarter Results.” Amazon.com, Inc. July 29, 2021.

8 Sand P. “Container Shipping — Onshore Disruption Leading to Record Delays and Profits.” BIMCO. Sept. 8, 2021.

9 “ATA Truck Tonnage Index Decreased 1.2% in July.” American Trucking Associations. Aug. 24, 2021.