Aligning Contract Clauses with Owners to Share Risk of Supply Chain Disruption

Between March 2020 and spring 2022, budgeting and buying out construction projects felt like a game of whack-a-mole. Some equipment and material we knew was likely to have an extended lead time or significant price increase, and others perhaps caught us by surprise.

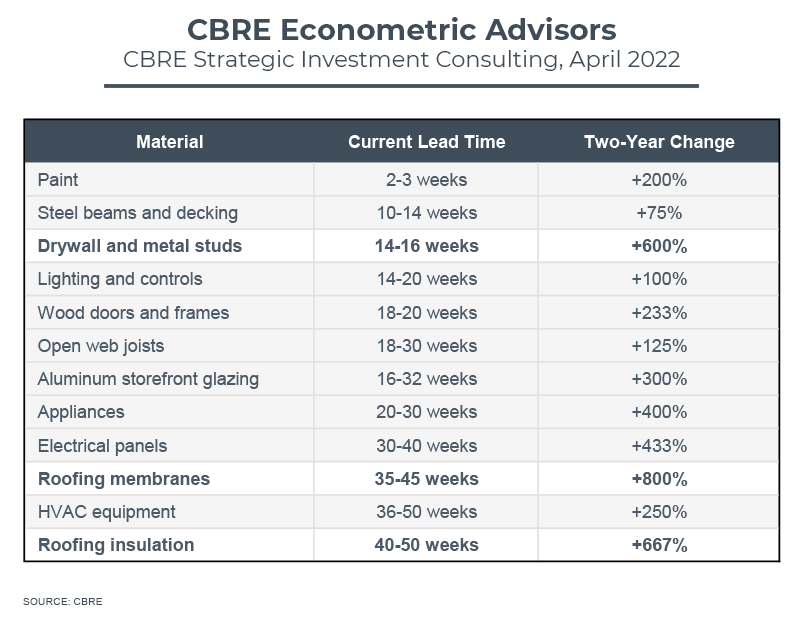

CBRE published the following chart in July 2022 as part of their Construction Cost Report, detailing the change in lead times that occurred over this period.

While many of these lead times declined since April 2022, we do not know how global supply chains will respond to increased tariffs and changes in global trade policy. We also do not know how and when prices for construction materials will escalate.

Contracts can and should be a tool that help all parties understand and equitably split the risk of construction projects in the face of heightened uncertainty. Furthermore, a project cannot be built without a team of partners. This team needs to be built before the work starts and often finds its initial shape during contract negotiations.

What Contractors Should Do: Playing Offense Instead of Defense

- Review the valid pricing windows for your proposals and consider adjusting down to 30 days or even 14 days (and change orders to 10 days or fewer).

- Negotiate updates to contract force majeure clauses.

- Example: “In the event that a party is unable to perform its obligations under this agreement due to an event outside its control, including but not limited to supply chain disruptions, pandemics, natural disasters or government actions…”

- Example: “In the event that a party is unable to perform its obligations under this agreement due to an event outside its control, including but not limited to supply chain disruptions, pandemics, natural disasters or government actions…”

- Consider introducing contract riders or provisions for price-impacted materials.

- Example: “If the price of materials significantly increases through no fault of the contractor, the contract sum shall be equitably adjusted by an amount reasonably necessary to cover the increased cost. As used herein, a ‘significant price increase’ shall mean any increase in price greater than 10% from the execution date of the contract.”

- Example: “If the price of materials significantly increases through no fault of the contractor, the contract sum shall be equitably adjusted by an amount reasonably necessary to cover the increased cost. As used herein, a ‘significant price increase’ shall mean any increase in price greater than 10% from the execution date of the contract.”

- Consider introducing contract riders or provisions for time-impacted materials.

- Example: “If the contractor is delayed at any time in the commencement or progress of the work due to a delay in the delivery of, or unavailability of, a potential time-impacted material beyond the control and without the fault of the contractor, its subcontractors, and material suppliers, the contractor shall be entitled to an equitable extension of the contract time…”

- Example: “If the contractor is delayed at any time in the commencement or progress of the work due to a delay in the delivery of, or unavailability of, a potential time-impacted material beyond the control and without the fault of the contractor, its subcontractors, and material suppliers, the contractor shall be entitled to an equitable extension of the contract time…”

- Consider using allowances and shared savings clauses.

- Example: “The contract sum was based on an electrical equipment price of $600,000. If the price exceeds $620,000 at the time equipment is purchased, then the contract shall be increased to reflect the price increase. If the price drops below $580,000 at the time equipment is purchased, then the contract price shall be decreased to reflect the price decrease.”

- Example: “The contract sum was based on an electrical equipment price of $600,000. If the price exceeds $620,000 at the time equipment is purchased, then the contract shall be increased to reflect the price increase. If the price drops below $580,000 at the time equipment is purchased, then the contract price shall be decreased to reflect the price decrease.”

- Establish early letters of intent to begin procuring material and equipment before full contract award.

- Publish key owner design decision dates and submittal approval dates on your critical path schedule and review these dates with owners prior to award to help drive accountability.

- Engage as early as possible with your suppliers, vendors and distributors; have them participate in early discussions with your end-user owners and general contractors to help influence the project procurement strategy.

Our remaining blog posts in this series will include the following additional strategies for managing price escalation and supply chain disruption and what to do in your business:

- Planning your projects to mitigate supply chain risk

- Drafting field look-ahead plans and executing well

If you would like to discuss specifics about your own supply chain challenges in relation to tariffs or other disruptions, please don't hesitate to reach out to me or another member of our team.