Planning Your Projects to Mitigate Supply Chain Risk

The current trade war is creating great apprehension throughout the industry with respect to potential price escalation and supply chain disruption. A contractor’s best opportunity to mitigate and manage project risks is in preconstruction and in the very early, post-award/pre-mobilization phase. In this article, we delve into two critical risk management tools that contractors can adopt and/or bolster in their pre-job planning efforts to hedge against market turmoil.

One of the hallmarks of successful projects and contractors is that they do pre-job planning really well. The new risk environment requires contractors to thoroughly plan their work, start planning sooner and increase the level of communication and collaboration of project teams.

Early and proactive buyout is one of the best tools for mitigating pricing risk. Your organization should be measuring and reporting the number of days it takes to complete 100% buyout of every project, and set an aggressive target to do so, depending on the size and scope of your projects. As an example, many successful organizations are targeting full buyout of projects within 30 days of contract award or before 10% completion of the post-award project schedule.

This requires expedited coordination between your company, designers, your customer and suppliers on getting submittals drafted, reviewed and approved. These discussions should begin prior to award , with key submittal review and approval dates placed on your construction schedule to drive transparency among all stakeholders.

Most project teams in the COVID-19 years would have put critical long-lead equipment or material procurement and delivery as one of the riskiest aspects of managing their projects. These risks are likely to return to construction with the current trade environment and likelihood of supply chain disruption.

Early buyout helps mitigate pricing risk but does not fully mitigate the risk of delayed deliveries. There are also two pre-job planning tools that all contractors should be updating and leveraging right now to help them better manage supply chain risk.

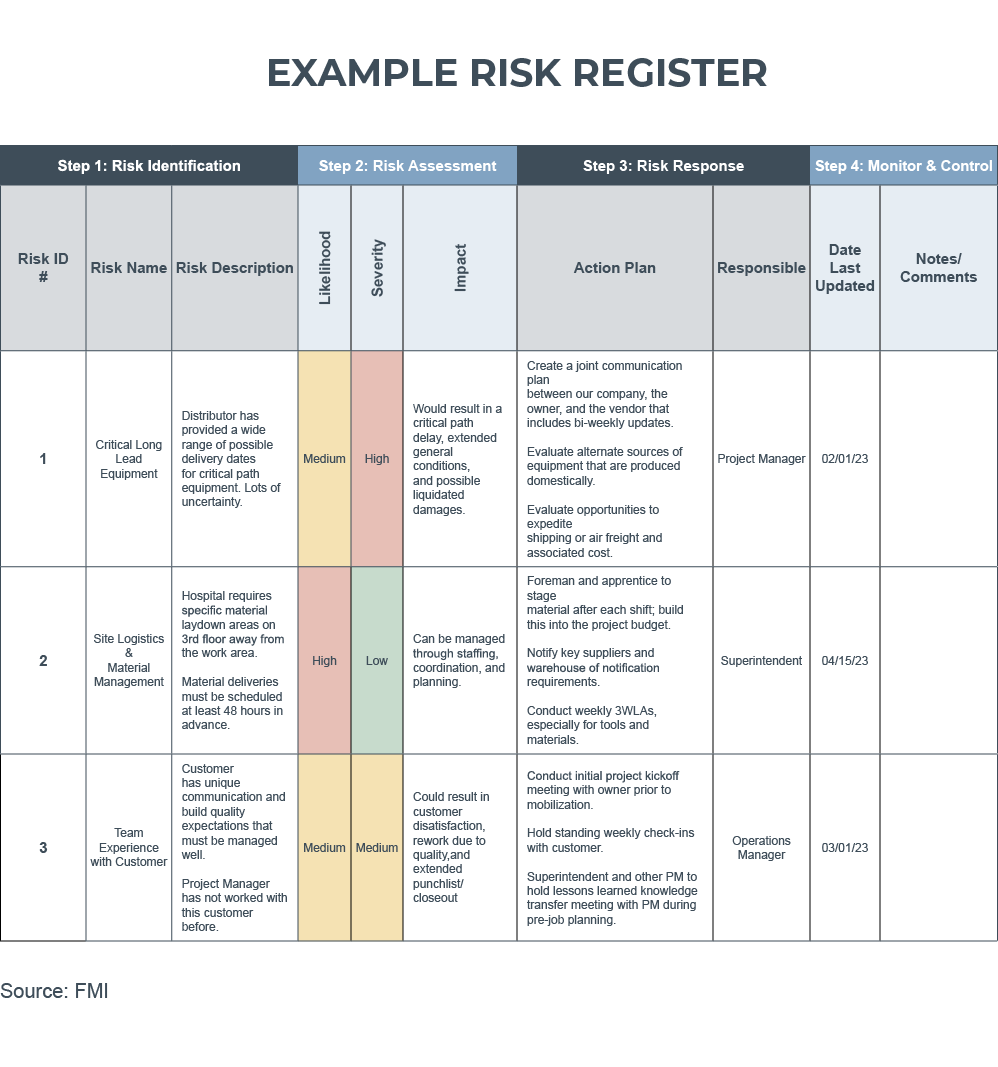

Risk Register

The first is a risk register or risk mitigation plan. This tool should be drafted during the estimate review process and updated during each stage of pre-job planning. The team should consider and document those risks most likely to be realized on their projects and those that would have the biggest overall impact on schedule, budget, customer experience or other project stakeholders.

The team should then think through what to do about each of them, how they would mitigate or lessen the impact of each project risk. A risk register can also be used to identify opportunities where, through proactive management, the project team may be able to deliver margin gain to the project and to your company.

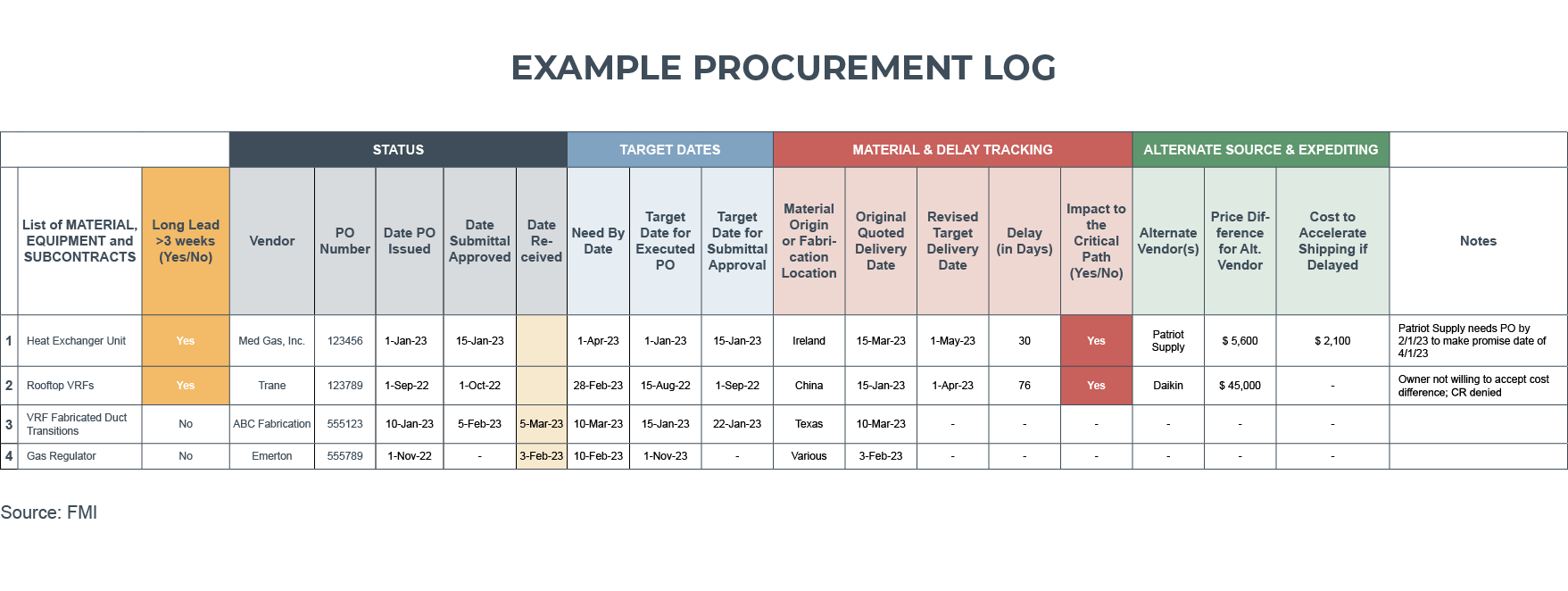

Procurement Log

The second tool is a detailed procurement log or buyout log. During the supply chain disruption of 2020 through 2022, we couldn’t rely on vendor target delivery dates to plan our work. Materials and equipment experienced unexpected vendor stockouts or customs holds during international shipping. This may occur again.

Procurement logs should be written during the early stages of a project. Best-in-class contractors are using their procurement logs as more than just a tool to track or witness what’s been ordered and when it will be delivered. They are using the procurement logs to understand and manage the risk of material delays, and to create a “plan B” for unexpected changes in material pricing or delivery that put the project at risk.

The procurement log should be started in the estimating/preconstruction phase prior to project handoff to operations and updated throughout the project until all deliveries to the job site are completed.

What Contractors Should Do: Playing Offense Instead of Defense

- Set aggressive targets for your teams to fully buy out their projects.

- Track buyout progress and report the procurement status of all projects weekly.

- Put key procurement dates, including submittals, on your critical path schedule that is published to owners, architects and your general contractor partners.

- Discuss these at or before time-of-award with all stakeholders so their accountability for helping achieve the desired project completion schedule is well understood.

- For major equipment or fabricated components, go beyond the confirming dates with the vendor and communicate upstream to the manufacturer to confirm your order’s place in the manufacturing queue, slated manufacturing time and target transit dates.

- Document expected project risks in a risk register, updated over time, so that all projects have an early plan to protect the project from margin fade or delays.

- Think creatively about ways to expedite material and equipment, even if it comes at a higher cost. Often the cost of expediting is far less than the cost of a project delay or downstream labor stacking.

- Ensure that procurement logs are updated weekly throughout execution.

- Consider updating your company’s procurement log with the following additions:

- Where is the material being manufactured or fabricated?

- How much has the quoted delivery date shifted since our initial quote?

- Is this material on the critical path?

- Who are the alternate vendors that might be able to supply the material? What was the price difference?

- Can we expedite this material? How? What would it cost?

The examples included herein are merely examples. Every contractor is unique, and the sophistication of their tools should reflect the risk associated with the work they do. A risk register for a $1 billion hospital project will be far more comprehensive and detailed than that for a $50 million warehouse. We encourage clients to build these tools from within, tailoring them to their organization and their work, to control their risks without burying their field personnel in administrative work.

Our remaining blog posts in this series will include the following additional strategies for managing price escalation and supply chain disruption – and what to do in your business:

Questions for Further Thought

Are you sometimes caught of guard by budget or schedule impacts related to ineffective procurement?

- Do your project managers proactively and formally manage risks and procurement?

- Does your organization leverage robust risk registers and procurement logs?

- What other approaches is your organization taking to manage risks related to potential price increases and supply chain disruptions?

Give us a call, we would love to talk shop and share ideas.