Tightening Your Project Selection Criteria and Estimate Review Process

It’s not clear what additional changes in U.S. and global trade policy will take place in 2025 but based on the initial tariff policies rolled out in early April, we can expect broad construction material prices to increase in 2025 by at least 5% to 7%, and possibly much more, pending future policy action.

We can also expect to begin seeing supply chain disruption in the form of extended lead times, uncertain delivery dates and potential stockouts of key construction materials and equipment associated with the global effects of new tariff policies and potential retaliatory measures from other countries.

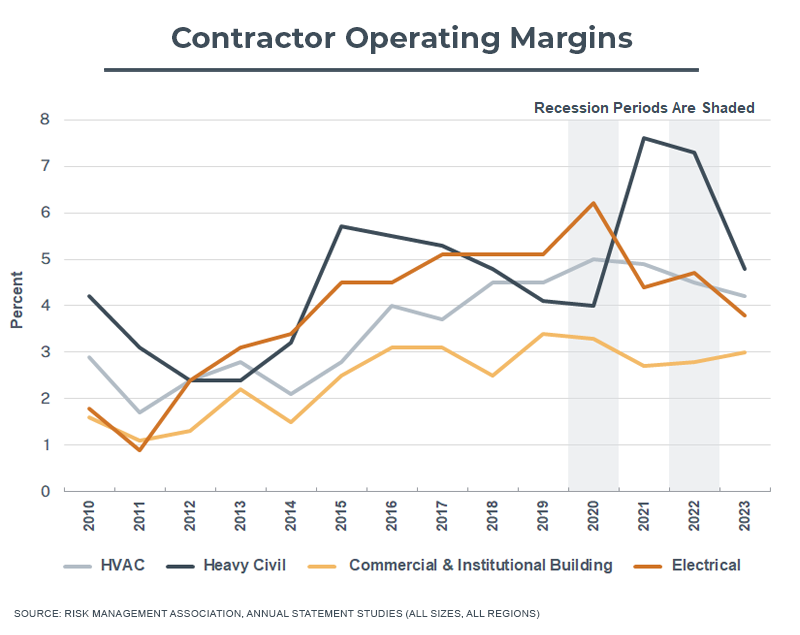

These price escalation and supply chain disruption factors represent additional risks to the inherently risky business of construction. Contractor bottom-line margins are incredibly thin, generally less than 5%. An average general contractor historically makes less than 3% operating margins each year. An average mechanical, electrical and plumbing (MEP) contractor historically makes less than 5%.

With these low margin profiles, one or two bad projects can spoil a year of otherwise profitable work! That is why it is critical for contractors to be disciplined in the work they pursue and take on. It’s even more important when exogenous market risks increase, like we are seeing today.

What Contractors Should Do: Playing Offense Instead of Defense

In a period of uncertainty, mediocre project opportunities tend to feel slightly more attractive to your business. They might not have great margin opportunities and might be with a difficult customer, but it would sure feel good to secure some backlog and keep your folks busy! Unfortunately, this approach can be perilous.

Contractors should continue to play offense during times of uncertainty. Now is the time to put additional effort into business development and customer intimacy strategies, proactively swimming upstream to widen and fill the funnel. This means driving an abundance of the right kind of opportunities into the top of the funnel, so you can be picky about which ones you eventually choose to pursue.

Tighten up your go/no-go process to become more selective in the projects you pursue, and double-down on rigorous review of your client proposals and project estimates.

- Ensure your organization has and is diligently using a go/no-go decision-making process to discuss and assess potential opportunities.

- Customer: What do we know about the customer? Would they be a good partner if or when the project might become challenged?

- Strategy: Is this project truly aligned with our strategy and target market(s)?

- Risk: Are there any risks that make this project unique and therefore a good fit or a bad fit for our business?

- Cash: What do we know about the customer’s source of financing, ability to pay and expected timeliness of payment? What are the potential impacts to our own cash flow?

- Margin: How would our company bring a competitive advantage to the project or generate outsized margin opportunities compared to our competitors?

- Resources: Do we have the resources available to price this project well and execute this project productively?

- Be much more selective about the work that you say “go” to and be more comfortable saying “no-go” to opportunities that might have been at the edge of your comfort zone before this period of uncertainty.

- In your estimate, identify ways to preserve or grow margins through attentive management of known risks. Consider incorporating:

- Dedicated site materials management and procurement planning.

- Partnering with subcontractors and suppliers instead of accepting the lowest bid.

- Selection of alternate materials at higher cost, lower risk of delay; budget for expedited freight.

- Storage of materials (and modification of builder’s risk policy to match).

- Other risk and insurance programs (e.g., bonds, subcontractor default insurance).

- Ensure your estimate review process requires input from operations and field leaders before being sent to a client. Include:

- Customer and past projects history

- Risk assessment and mitigation plan

- Project staffing plan

- Execution schedule and constructability

- Subcontractor and vendor selection

- Buyout plan and schedule

- Alternate suitable materials and equipment

- Contingencies and allowances

Our remaining blog posts in this series will include the following additional strategies for managing price escalation and supply chain disruption – and what to do in your business:

- Aligning contract clauses with owners to share risk

- Planning your projects to mitigate supply chain risk

- Stopping supply chain risks from impacting the field

If you would like to discuss specifics about your own supply chain challenges in relation to tariffs or other disruptions, please don't hesitate to reach out to me or another member of our team.