Operational Excellence Begins In Preconstruction

Preconstruction is often misunderstood. While many firms still treat it as a transactional phase — a checklist of budgets, estimates and approvals — the best-performing contractors recognize it as something far more strategic.

For CEOs, presidents and business leaders aiming to increase profitability, reduce risk and ensure predictable outcomes, preconstruction is the foundation of operational excellence. Industry Insight: Projects with formal preconstruction processes see up to 30% fewer cost overruns and 25% faster delivery timelines.

Why Preconstruction Matters More Than Ever

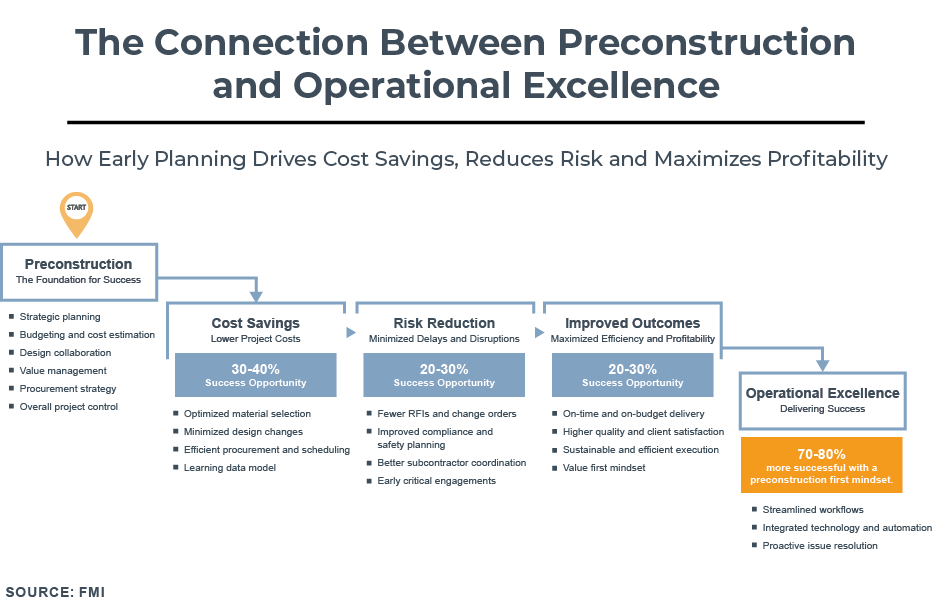

According to industry benchmarks from Construction Industry Institute, Lean Construction Institute and Design-Build Institute of America, 70-80% of a project’s success is influenced before construction begins. That’s because preconstruction directly drives three critical performance outcomes:

Cost Savings (A well-executed preconstruction phase can contribute to 30–40% in potential cost savings)

Preconstruction enables smarter decision-making around materials, procurement and design, leading to lower project costs and stronger margins.

Examples:

- Optimized material selection

- Minimized design changes

- Efficient procurement and scheduling

- Data-driven estimating models

Result: Managed costs = Higher profit margins

Industry Insight: Forward-thinking preconstruction teams are increasingly leveraging proactive client engagement to save costs and increase speed to market without sacrificing quality.

Risk Reduction (Effective preconstruction can reduce project risks by 20–30%)

Proactive planning reduces change orders, delays and downstream surprises, driving more reliable outcomes.

Examples:

- Fewer requests for information and change orders

- Early compliance and safety planning

- Better subcontractor coordination

- Early trade engagement

Result: Informed schedules = Fewer delays and cost overruns

Industry Insight: The best preconstruction teams drive internal alignment around fee structures, cost-recov- ery mechanisms and the project’s overall profit strategies throughout the preconstruction lifecycle.

Improved Project Outcomes (Strong preconstruction planning can improve overall project outcomes by 20–30%)

Preconstruction creates alignment across design, delivery and client expectations, resulting in smoother execution and greater client satisfaction.

Benefits:

- On-time and on-budget delivery

- Higher-quality outcomes

- Sustainable and efficient execution

- Value-first decision-making

Result: Managed execution = Stronger margins and repeat business

Industry Insight: Preconstruction isn’t just about managing individual projects; it’s also the engine of throughput. By reducing cycle time and increasing win rate, high-performing preconstruction teams optimize departmental efficiency and create more predictability in the pipeline and backlog.

Aligning Business Strategy With Project Execution

Preconstruction is where your business strategy becomes your project reality. It is the most effective phase to align:

- Client expectations. Set a clear vision of success.

- Project scope. Prevent scope creep.

- Design intent. Optimize for constructability and efficiency.

- Budget certainty. Eliminate costly surprises and rework.

- Schedule feasibility. Account for phasing, procurement and workforce availability.

When owners, designers, general contractors and trade partners are able to engage early—thanks to the leveraging of target value delivery and lean planning—every decision supports the business case, not just the building plan.

Preconstruction is a Team Sport — And the Best Teams Win Together

Yet understanding preconstruction is just the first step. You need to engage the right people on your teams and establish processes to make it a success.

For too long, preconstruction was viewed narrowly as “just estimating.” But the best-performing firms now treat it as a means of cross-functional collaboration that protects margin, reduces risk and sets the entire project up for success long before boots hit the ground.

This is where the shift from reactive coordination to proactive control happens. Through strategic precon- struction, stakeholders can align and engage in better decision-making to avoid costly late-game surprises.

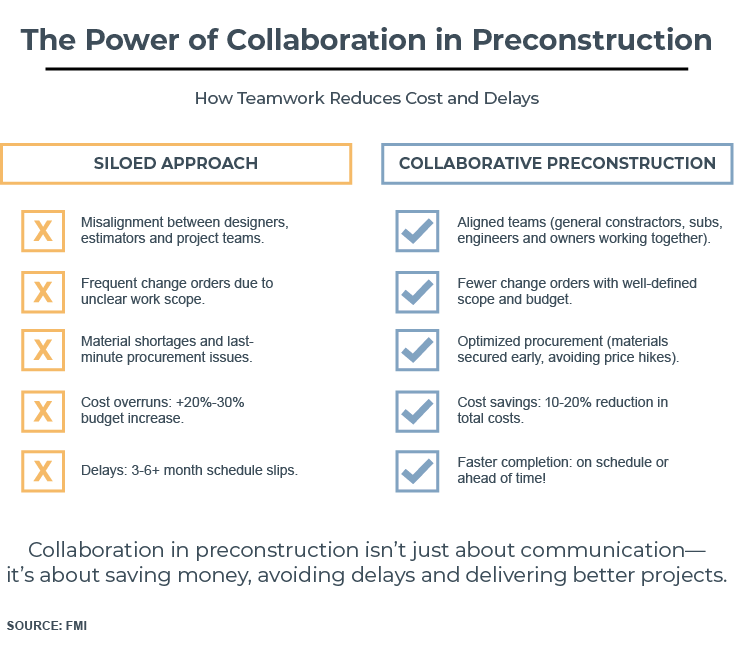

Why It Matters More Than Ever

Contractors leveraging structured, collaborative preconstruction practices experience a measurable impact.

- Projects with strong preconstruction practices see 40% less budget escalation between initial estimates and final costs, due to early risk identification and scope clarity.

- Collaborative preconstruction leads to 30% fewer schedule delays by resolving design, logistics and pro- curement issues before construction begins.

- Integrated preconstruction teams see 7-10% reductions in overall project time and cost by optimizing design decisions, sequencing and trade coordination early.

These aren’t hypothetical gains; they’re actual wins driven by early decision-making, active risk mitigation and strengthened team alignment.

What High-Performing Contractors are Doing Differently

- Engaging field leaders early: Take the case of a national health care builder who began involving supers in design-phase constructability reviews. They flagged an unreachable ceiling cavity before framing, avoiding $150,000 in rework and saving weeks of delay.

- Bringing trade partners in during design: Using TVD, a contractor working on a life sciences facility involved their mechanical, electrical and plumbing (MEP) partners early. The result? A 10% reduction in MEP costs with no compromise in performance, thanks to smarter layout decision-making and prefabrication opportunities.

- Running collaborative pull planning during preconstruction: A heavy civil firm facilitated pull planning workshops that included designers, owners and trades. They uncovered a critical logistics sequencing issue that would’ve cost them weeks if found in the field.

- Using real-time cost modeling: Instead of static budgets, leading preconstruction teams build dynamic cost models, integrated with design changes, material trends and scope shifts. For example, a framing and drywall contractor involved early in design can input current framing pricing, framing crew availability and productivity rates. When wall layouts or ceiling types change, the model immediately reflects cost and schedule impacts, giving the owner the clarity to make timely, well-informed decisions.

When preconstruction is done right, it’s not just about numbers. It’s about building trust, enabling agility and delivering projects with greater certainty.

Leveraging Data to Drive Smarter, Collaborative Preconstruction

In today’s environment, successful preconstruction isn’t just about following instinct — it’s about using data to collaborate, break down silos and prevent costly surprises.

High-performing teams use data to:

- Align scope, schedule and budget early early in the process, reducing change orders and miscommunication.

- Benchmark costs using historical data to drive informed pricing and avoid overruns.

- Leverage artificial intelligence-enhanced estimating tools for faster takeoffs and risk visibility.

- Track design changes and procurement impacts in real time to avoid last-minute material issues.

- Model cost/value trade-offs to support better decision-making before critical buyout milestones.

When data is siloed, teams miss key risks and opportunities. But when it’s shared and connected, collaboration improves and so do project outcomes.

The ROI of Preconstruction Excellence: From Siloed Costs to Collaborative Gains

Some companies still view preconstruction as an added cost — but failing to invest in early planning and collaboration is far more expensive. Research continues to show that strategic, data-informed and collaborative preconstruction directly improves cost, scheduling and overall outcomes.

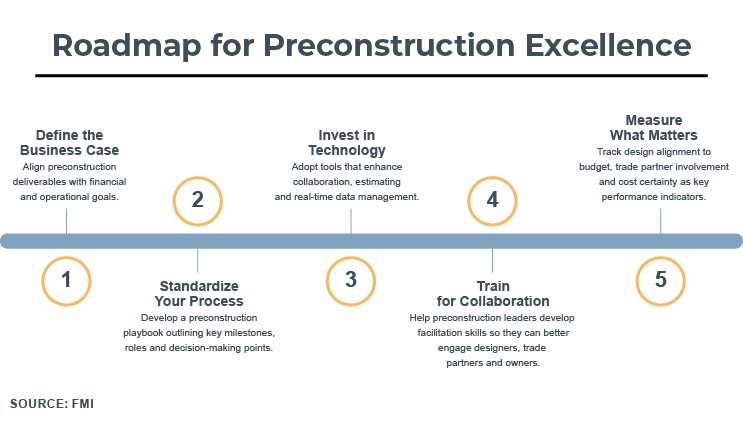

Action Steps for Preconstruction Leaders

If you’re serious about turning preconstruction into a value-driving business function, here’s where to start:

- Define the business case. Align preconstruction efforts with enterprise-level financial and operational goals.

- Standardize the process. Build a consistent preconstruction playbook with clear milestones, roles and decision-making points.

- Invest in the right technology. Adopt integrated tools that enhance collaboration, estimating, procure- ment and real-time data visibility.

- Train for facilitation, not just estimating. Equip preconstruction leaders with the skills to align designers, subcontractors and owners in the work.

- Measure what matters. Track key performance indicators like design-to-budget alignment, trade partner engagement and cost certainty, not just estimate accuracy.

The return on investment (ROI) of preconstruction isn’t theoretical, it’s measurable. When companies shift from siloed estimating to collaborative planning, they consistently reduce risk, improve margins and deliver better projects faster.

Turning Preconstruction Into a Competitive Advantage Starts Today

Remember, operational excellence isn’t the result of luck or last-minute heroics — it’s built long before a project breaks ground. It starts with how you plan, work across teams and stakeholders and make key decisions in preconstruction.

For executives and preconstruction leaders, transforming this phase from a transactional task into a strategic advantage may be the most important move you can make to:

- Increase profit margins

- Deliver projects with greater certainty

- Strengthen client relationships

- Build long-term business value

In today’s competitive market, companies that invest in collaborative, data-driven preconstruction consistently outperform those that rely on siloed estimating and late-stage decision-making. The most successful firms don’t just manage preconstruction — they lead with it. If you’re ready to elevate preconstruction from the cost center to competitive advantage, we’re here to help.