Impact of Tariffs on Construction: What Contractors Should Do

Recently, new U.S. tariff policies and global retaliatory measures introduced nearly unprecedented pricing uncertainty into construction. In a recent blog post about February's steel and aluminum tariffs as well as one targeted to building product manufacturers, FMI outlined a few considerations. Now with the U.S. implementing global tariffs in April, it is not clear what additional changes in U.S. and global trade policy will take place in 2025.

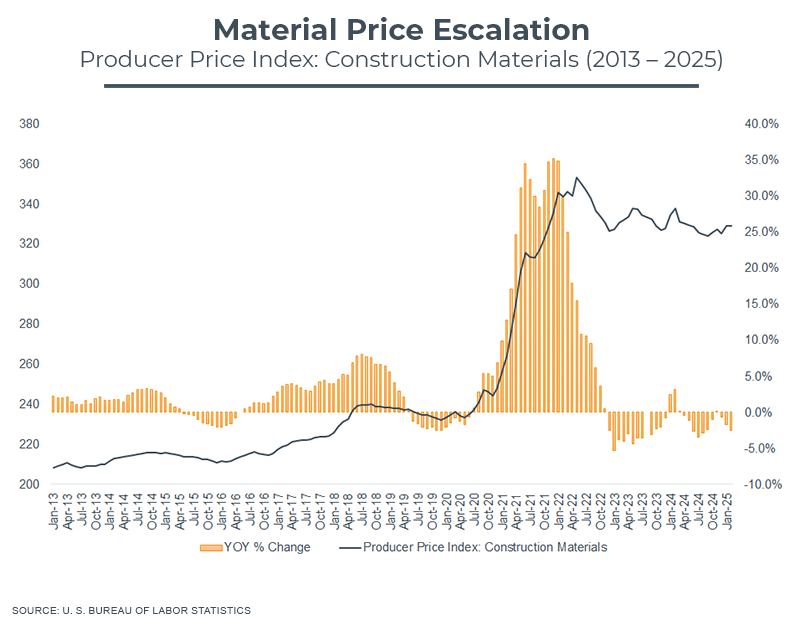

Based on the initial tariff policies rolled out earlier this month, we can expect broad construction material prices to increase in 2025 by at least 5% to 7%, and possibly much more, pending future policy action.

We can also expect to begin seeing supply chain disruption in the form of extended lead times, uncertain delivery dates and potential stockouts of key construction materials and equipment associated with the global effects of new tariff policy and potential retaliatory measures from other countries.

What Contractors Should Do

Construction companies experienced a period of rapid material price escalation and unprecedented supply chain disruption during 2020 and 2021. During these two years, your business almost certainly made changes to how it evaluated contracts, planned procurement, conducted buyout and executed work. Your organization learned how to do business in the face of this uncertainty.

This year your business should double-down on those things that worked well from 2020 to 2022. These tools include:

- Educating customers on the risk to their projects

- Tightening your project selection criteria and estimate review process

- Aligning contract clauses with owners to share risk

- Planning your projects to mitigate supply chain risk

- Stopping supply chain risks from impacting the field

In the coming weeks, we’re going to unpack these best practices in separate blog posts that help your company adapt and manage this unprecedented disruption.

If you haven’t yet done so, now would be a good time to:

- Reach out to your customers and discuss the likely impacts to their projects, your business and the usefulness of letters of intent to purchase materials and equipment.

- Sit down with your purchasing managers and preconstruction leaders to re-establish your planning and procurement best practices.

- Review and assess how much contingency you’re currently carrying in your project budgets (pre-award and active jobs).

- Double-down on measuring and reporting the number of days from project award to 100% buyout on all projects.

- Huddle with your project executives, project managers and field leaders to let them know that your company has weathered this storm before, and you know how to do it again.

If you would like to discuss specifics about your own supply chain challenges in relation to tariffs or other disruptions, please don't hesitate to reach out to me or another member of our team.